- Home

- Products

- About us

- Services

- ODM/OEM

- Solution

- NEWS

- Contact us

- Home

- Products

- About us

- Services

- ODM/OEM

- Solution

- NEWS

- Contact us

| Product Title | Kids Seamless Jacket |

| Brand | Harvest SPF Custom Activewear Manufacturer |

| Model Number | WT3609 |

| Composition | Knitting: strip/wave parts: Nylon 72.2% Polyester fiber 22.8% Spandex 5.0% Other parts: Nylon 76.1% Polyester fiber 19.0% Spandex 4.9% Woven part: 100% nylon Filling: 90% goose down |

| Sizes Available | XS/S, M/L, XL/XXL |

| Color Range | Customized |

| Minimum Order Quantity | Available from 300 pieces per style per color per size. |

| Label & Tag | Fully customizable to reflect your brand |

Custom Kids Seamless Down Jacket | OEM Technical Outerwear Manufacturer

Introducing our premium Kids Seamless Down Jacket, expertly engineered with innovative hybrid construction for superior cold-weather protection. This advanced jacket features sophisticated material composition with specialized knitting in strip/wave parts (72.2% Nylon, 22.8% Polyester, 5.0% Spandex) and other seamless areas (76.1% Nylon, 19.0% Polyester, 4.9% Spandex), combined with 100% Nylon woven panels and premium 90% Goose Down filling for exceptional thermal insulation.

Featuring cutting-edge seamless knitting technology and strategic fabric placement, this technical jacket delivers a comfortable, body-adaptive fit that eliminates bulk while maximizing warmth. The premium goose down filling provides outstanding heat retention in cold conditions, while the spandex-enriched knit sections ensure complete freedom of movement for active children. The hybrid construction balances lightweight comfort with durable performance, making it ideal for various outdoor activities and everyday winter wear.

Available in kids’ sizes XS/S, M/L, XL/XXL to accommodate different age groups and body types, this premium jacket offers comprehensive customization options to meet your brand’s specific design requirements. The seamless technology allows for modern styling without traditional seam limitations, while the woven elements provide structural integrity in high-stress areas.

With minimum order quantities starting from 300 pieces per style per color per size, we provide reliable manufacturing solutions for brands seeking high-performance children’s outerwear. Enhance your collection with our complete branding options, including custom labels, heat transfer logos, and specialized trim details to strengthen your market positioning in the competitive children’s apparel industry.

We offer techpack based on your country, and can deliver prototype 2 times before your bulk order.

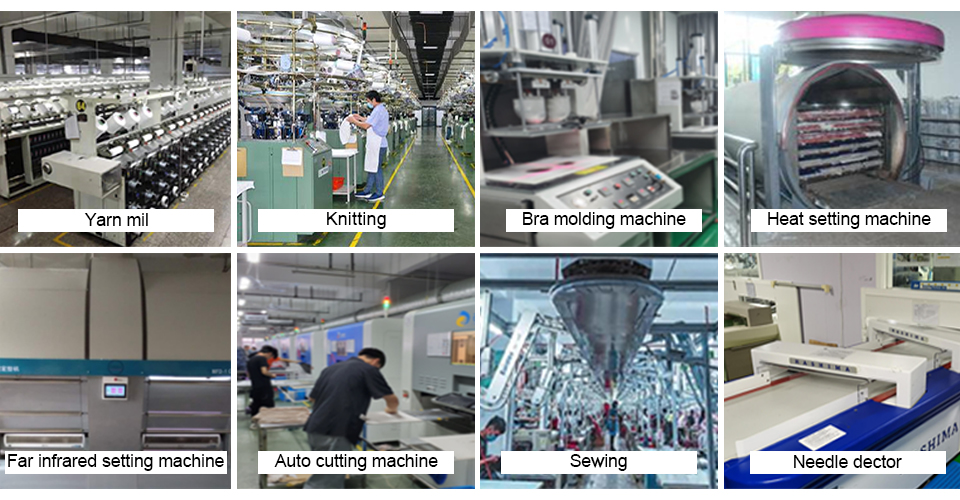

We are proud of our santoni knitting, flat-lock and high quality stitching, and we provide round neck, v neck according to your needs. Furthermore, we bring your designs to life with custom jacquard, 3D structure to fully realize your brand vision.

· Innovative Hybrid Material System

Featuring advanced combination of seamless knitted panels with specialized stripe/wave sections (72.2% nylon, 22.8% polyester, 5.0% spandex) and other areas (76.1% nylon, 19.0% polyester, 4.9% spandex), combined with 100% nylon woven fabric and premium 90% goose down filling for targeted warmth and maximum flexibility.

· Advanced Thermal Regulation

Premium goose down insulation in core areas provides exceptional warmth while maintaining excellent breathability. The intelligent material distribution ensures comfortable body temperature in varying conditions, keeping children warm without overheating during activities.

· Enhanced Mobility & Seamless Comfort

Body-mapped seamless knitting technology eliminates chafing points and creates comfortable, flexible fit for active movement. The strategic spandex content throughout ensures complete freedom of movement for play and outdoor activities.

· Lightweight & Highly Packable

Engineered for easy packing and travel convenience. The compact construction allows the jacket to compress into minimal space, making it ideal for family outings and outdoor adventures without sacrificing warmth or performance.

· Practical Functional Design

Includes adjustable hood for optimal weather protection, secure zip pockets for essentials storage, and elasticated cuffs with hem for secure fit during active movement. The hybrid construction balances durability with everyday practicality.

· Versatile All-Weather Performance

Perfect as standalone outerwear in cold conditions or as insulating mid-layer in extreme weather. The smart design transitions seamlessly from playground activities to family adventures.

· Child-Friendly Customization

Available in kids’ sizes XS/S to XL/XXL with complete color customization and safe, durable branding options. MOQ starts from 300 pieces with flexible production terms for children’s wear brands.

| Product Description | Kids Seamless Jacket |

| Categories | Jacket |

| Design | OEM / ODM / Design Service |

| Functional Material Options | Nilit®, Tactel®, Meryl® Skinlife, Creora®, thermalite®, coolmax®,Dryarn®,Lava®, bamboo charcoal,merino wool, drirelease,Tencel®… |

| Key Functions | Our Kids Seamless Down Jacket is expertly engineered to deliver superior warmth and comfort in cold conditions:

Premium Down Insulation & Warmth Retention |

| Sizes | XS/S, M/L, XL/XXL with regional size charts available for accurate fit. |

| Color Options | Custom colors can be matched to Pantone numbers. |

| Available for order | 300 pieces per style per color per size |

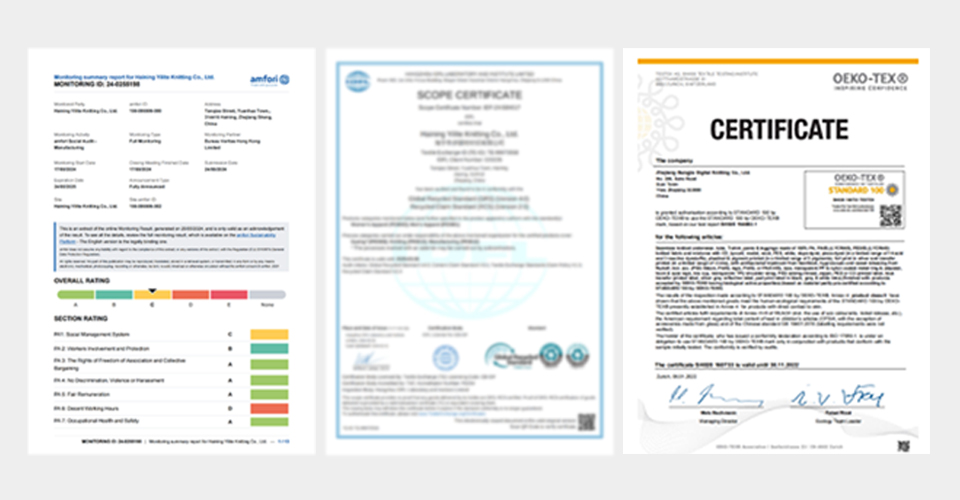

| Certifications | OEKOTEX 100 |

| Packing | Each Jacket is individually packed, with options available for bulk packing as required. such as polybag, printed bag or boxes |

| Shipping | Flexible shipping options are available: By sea By air Through express services like DHL, UPS, TNT, etc. |

| Delivery Time | Delivery is expected within 40-70 days upon approval of pre-production samples |